All Aura systems are designed in close partnership with our customers to meet their specific needs.

Discover high-quality industrial heating solutions at AURA Process Heat.

Crafted 100 % in-house in our production facilities in Germany, our products guarantee certified quality, reliability, and precision. Choose from a diverse range of heating options, including electrical heating (thermal oil or steam), fired heating (thermal oil or water bath), and solar thermal energy.

Our experienced team caters to various industries, including chemical, petrochemical, paper, food, nonwoven, textiles, plastic, wood, and composites. Expect competitive pricing and tailored solutions for your specific needs when you choose AURA Process Heat.

Discover the efficiency and versatility of electrical heating. With precise control and minimal environmental impact, electrical heating systems offer a sustainable solution for various industrial and commercial needs. Explore our Electrically Heated Thermal Oil System and Electrically Heated Steam Boiler, designed to seamlessly integrate into existing setups and provide reliable heating across different industries.

Electrically Heated Thermal Oil System

What Our Electrically Heated Thermal Oil System Offers:

Efficient and low-wear, our thermal oil heating system eliminates the need for extra boiler rooms. It seamlessly integrates into existing production setups, offering precise and gentle heating suitable for various industries, from food to pharmaceuticals, crude oil treatment to biogas refinement.

Electrically Heated Steam Boiler

What Our Electrically Heated Steam Boiler System Offers:

Efficient and easy-to-use, our electrically heated system warms water with electric heating flanges, creating versatile steam for industrial needs. Precise controls maintain consistent water temperature and regulate steam pressure. Tailor it further with an optional process for superheated steam, catering to your specific application.

Exemplary system: 0,3 MBtu/h, 43,5 psi (g) – 58,0 psi (g), with superheated steam 572°F

Exemplary system: 0,3 MBtu/h, 43,5 psi (g) – 58,0 psi (g), with superheated steam 572°F

Explore the world of fired heating, a reliable and efficient method for various industrial applications. Our Fired Thermal Oil Heating System and Water Bath Heater for Natural Gas Preheating exemplify this technology’s versatility and effectiveness.

Fired Thermal Oil Heating System

What Our Electrically Heated Thermal Oil System Offers:

Engineered for reliable operation, our thermal oil heating systems boast robust wear protection and straightforward usability. Unlike traditional steam and water systems, thermal oil maintains low pressure, even at elevated temperatures of up to 806°F. Our innovative design incorporates a thermal oil flooded reversing plate, optimizing heat transfer and prolonging system lifespan by efficiently cooling the rear wall. With virtually maintenance-free operation and mitigation of corrosion and freezing risks, AURA systems deliver unmatched performance and assurance.

Examplary system built by AURA

Examplary system built by AURA

Water Bath Heater For Natural Gas Preheating

What Our Water Bath Heater System Offers:

Our fully automatic water bath heaters are engineered for precise heat treatment in natural gas expansion and crude oil heating applications. Designed for outdoor use, they are fully weatherproof for reliable operation in any environment. With a special high-pressure tank, AURA heaters are compact and seamlessly integrate into industrial systems, ensuring efficiency and convenience.

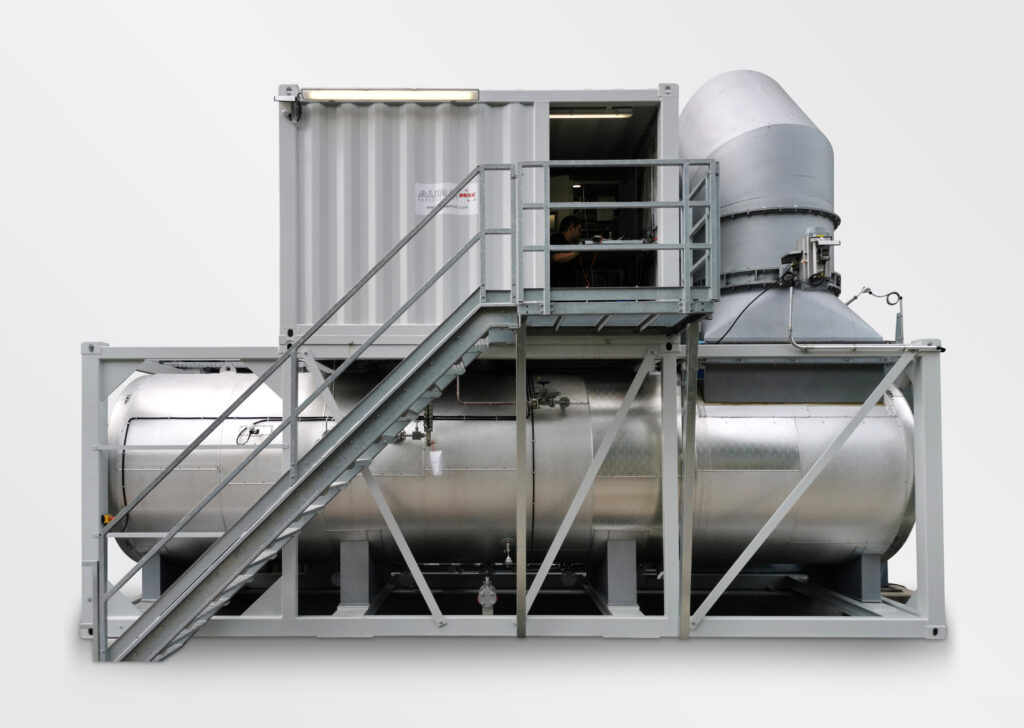

Exemplary system built by AURA: 4,1 MBtu/h, 3.532 ft³/h, ΔT 20 F

Exemplary system built by AURA: 4,1 MBtu/h, 3.532 ft³/h, ΔT 20 F

Experience the transformative potential of solar energy with AURA’s Solar Thermal Energy systems. Step into a world where sunlight powers efficient heating, seamlessly integrated by our expert team. Explore the pinnacle of renewable energy technology, customized to suit your specific needs.

What Our Solar Thermal Energy System Offers:

AURA Concentrated Solar Thermal (CST) technology harnesses sunlight with precision, using mirrors to generate high heat levels. Unlike photovoltaic or CSP systems, it directly provides heat, leading to superior efficiency.

In systems like parabolic troughs or linear Fresnel setups, sunlight is focused onto receiver tubes where a heat-transfer fluid absorbs the concentrated heat. This fluid then transfers the heat to consumers, such as heat exchangers.

CST systems offer remarkable thermal efficiency but require expertise for design and integration. Our Balance of Plant (BoP) unit manages this, ensuring efficiency and safety.

At AURA, we excel in BoP design and fabrication, offering pre-fabricated turnkey systems for easy installation, even in harsh environments.

As partners of the MODULUS project, focused on integrating Solar Heat for Industrial Processes (SHIP), we develop modularized BoP systems adaptable to various projects.

All AURA systems are crafted collaboratively with our clients to meet their unique needs.

Unlock the potential of waste heat with AURA’s innovative renewable energy solutions. From harnessing clean gas streams to utilizing flue gas temperatures, our systems offer a practical approach to sustainability in industrial processes. Maximize energy efficiency and minimize waste with our tailored waste heat recovery solutions.

Steam Generator, Flue Gas Heated

What Our Steam Generator Offers:

This advanced technology efficiently converts clean gas stream heat into high-quality steam. By replacing traditional steam generators, it offers a seamless transition or backup option for existing systems. Our solution significantly reduces CO2 emissions, contributing to a sustainable environment.

Thermal Oil System, Flue Gas Heated

What Our Thermal Oil System Offers:

This system can harness flue gas temperatures of up to 2192°F, offering a practical approach to utilizing waste heat. Integrating this technology can lead to enhanced sustainability in industrial processes, accompanied by significant reductions in primary energy costs and CO2 emissions.

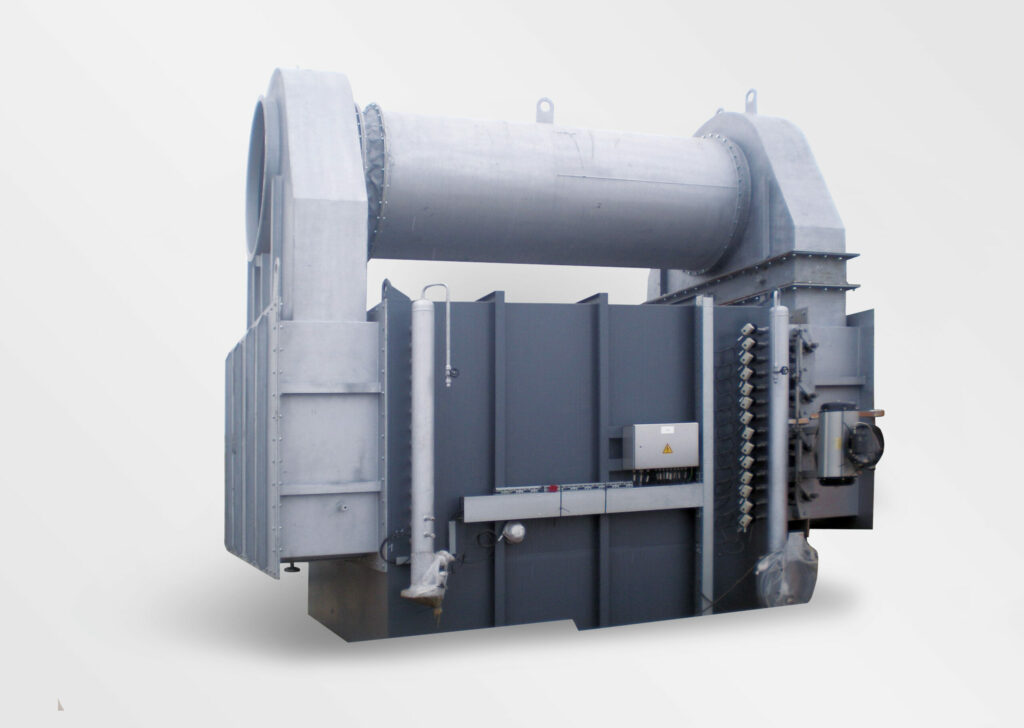

Thermal oil heating system for the use of flue gas

Thermal oil heating system for the use of flue gasTurbine Waste Heat Recovery Unit (WHRU)

What Our Turbine Waste Heat Recovery Unit Offers:

Turbine operations generate significant amounts of waste heat through flue gases, often left untapped. Heat recovery presents an opportunity to enhance both the efficiency and sustainability of production processes. The AURA waste heat recovery system specializes in capturing and utilizing the heat from turbine flue gases, extending its usability to other processes within a temperature range of up to 806°F. Moreover, by incorporating an additional afterburner, this system can also effectively harness lower temperature flue gases. With an impressive output potential of up to 4,1 MBtu/h, the AURA system stands as a reliable solution for maximizing energy efficiency and minimizing waste in industrial operations.

Exemplary system: 4,1 MBtu/h[/captionFF

Exemplary system: 4,1 MBtu/h[/captionFF

After the click you can look directly into our

calendar and choose a suitable appointment

with one of our employees.

AURA GmbH & Co. KG

Siebeinstrasse 3 (Zone 2)

76726 Germersheim, Germany